Capacity Range

Output

Safety Code

Environment

Most Popular Products

Load Cell Shopping Made Easier

One Place. Endless Load Cell Solutions.

Precision Load Cells for Every Application

High-performance, reliable, and built to meet the demands of industries from manufacturing to research.

60051 Single Point Load Cell

$113.00 – $250.00Price range: $113.00 through $250.00 Inc Shipping

Model 1130 – Stainless Steel Single-Point Load Cell

$325.14 – $855.64Price range: $325.14 through $855.64

SQB- Single-Ended Beam

$388.93 – $414.85Price range: $388.93 through $414.85 Inc Shipping

Model- 1510 Hermetically Sealed Single-Point Load Cell

$388.93 – $1,865.00Price range: $388.93 through $1,865.00 Inc Shipping

The Official VPG Partner for Precision Solutions | AU

At Sands Industries, we bring precision to every corner of Australian industry. As the official partner of VPG Sensors, we deliver high-quality sensors, gauges, and load cells that businesses trust. Our team combines technical expertise with hands-on experience to ensure every solution meets exacting standards. From design consultation to installation, we are committed to making complex measurements simple and reliable. With SandsIndustries.com.au, SensorandGauges.com, LoadCellShop.com.au, we make advanced weighing and sensing technology accessible across Australia.

Mission

Deliver accurate, reliable, and innovative measurement solutions to empower Australian industries.

Vision

Be Australia’s leading hub for sensors, gauges, and load cells, trusted by every sector.

Expertise

Decades of hands-on experience in precision measurement and industrial solutions.

Official Distributor

Proudly partnered with VPG Sensors to offer genuine, high-performance products.

Shop from wide range of load cells and sensors

Need Help Choosing a Load Cell? Get a Free Consultation & Recommendation Today!

Choosing the right load cell doesn’t have to be complicated. Follow these four simple steps to confidently identify the load cell that meets your needs and keeps your operations running smoothly.

Determine the type of force you need to measure; tension, compression, or both and the required capacity and precision.

Assess temperature ranges, humidity, vibration, and other environmental factors that could affect performance.

Choose between popular types like S-type, Shear Beam, Compression, or Platform load cells based on your application needs.

Ensure the load cell meets accuracy requirements, is compatible with your data acquisition system, and allows for easy installation and calibration.

One Stop For Load Cell solution

Why Choose Our Load Cells

Official Partnerships: Leverage the expertise of VPG Sensors — a globally trusted, best-in-class brand with decades of experience. When you shop with us, you get nothing but the highest-quality sensors and gauges, backed by years of industry know-how.

Industrial-Grade

Built to withstand harsh environments, our load cells maintain performance under extreme conditions.

Trusted Expertise

Decades of experience supplying Australia’s leading industries, delivering both products and guidance you can trust.

Integration Support

Mounting assemblies, instruments, and accessories included to simplify installation and boost performance.

Official VPG Sensor Partner

At Sands Industries, our official partnership with VPG Sensors puts decades of global expertise at your disposal. This means you’re not just buying a sensor — you’re investing in reliability, precision, and peace of mind. All products are genuine and certified, eliminating the risk of counterfeits or sub-standard alternatives.

When you shop with us, you gain:

Manufacturer-backed warranties for complete confidence.

Access to the latest sensor technology and performance upgrades.

Expert guidance from a team trained and recognized by VPG, ensuring the right solution for your application.

This partnership ensures that your measurement solutions are accurate, durable, and trusted worldwide, giving you the competitive edge you need.

Everything Under One Roof

We offer a comprehensive range of load cells, sensors, gauges, and accessories, designed to meet the needs of Australian industries across manufacturing, logistics, aerospace, and more. But we don’t stop at standard products. If your project demands something unique, we provide custom-built load cells tailored to your exact specifications.

Benefits of our full-service approach:

One-stop shopping: Save time and streamline procurement by sourcing all measurement equipment from a trusted supplier.

Custom engineering: From unusual load ranges to specialized mounting configurations, we’ll design a load cell that works exactly for you.

Integrated solutions: Compatible sensors, gauges, and accessories that work together seamlessly.

Our approach ensures that no matter how simple or complex your project, you get the exact solution you need — nothing less, nothing unnecessary.

Guidance You Can Count On

Precision measurement is only as good as the support behind it. Our team of experienced professionals is here to help at every stage — from product selection to installation and maintenance. With Sands Industries, you don’t just get a product; you get decades of technical expertise in the palm of your hand.

Here’s what you can expect:

Hands-on technical advice: Choose the right sensor or load cell for your exact application.

Installation and maintenance support: Maximise performance and longevity of every device.

Fast and reliable shipping across Australia: Ensure your projects stay on schedule.

Proven industry trust: Hundreds of Australian businesses rely on us for accuracy, quality, and consistency.

With our combination of expertise, support, and reliability, working with Sands Industries guarantees optimal performance from day one.

FAQs: Choosing the Right Load Cell

Our team of seasoned industry experts is available to advise you at every stage. We analyse your requirements, suggest the ideal type, and even provide custom solutions if needed — ensuring you get the right load cell, every time.

Checklist: How to Choose the Right Load Cell or Sensor

1. Identify Your Application

Determine if the measurement is tension, compression, or shear.

Understand the environment: indoor, outdoor, wet, dusty, high vibration.

Consider the type of equipment it will integrate with (scales, machinery, testing rigs, etc.).

2. Determine Capacity Requirements

Estimate the maximum expected load.

Add a safety margin (typically 10–20% above maximum load).

Decide if single-point or multiple load cells are needed for the platform.

3. Check Platform Size and Mounting

Measure the platform dimensions to ensure compatibility.

Identify mounting style: bolt-on, flange, through-hole, or custom.

Confirm the footprint can accommodate your setup without obstruction.

4. Choose the Load Cell Type

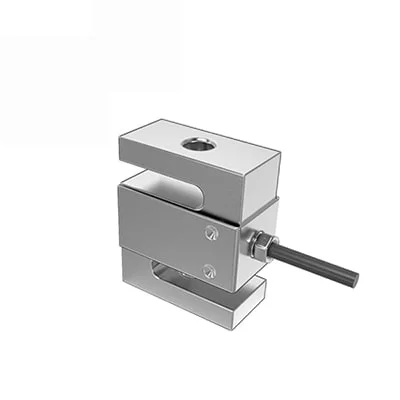

S-type: Tension and compression applications, medium to high capacity.

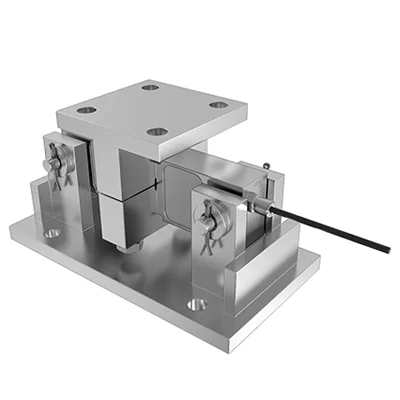

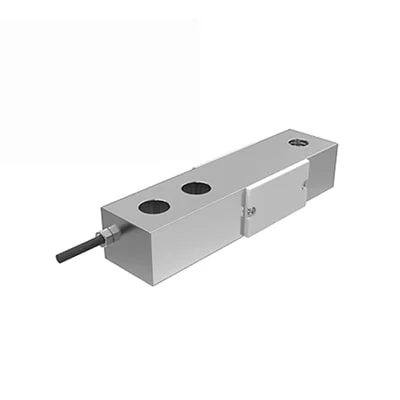

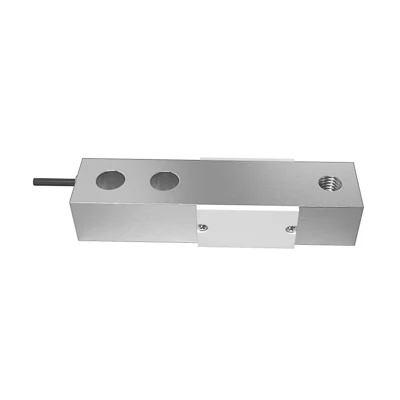

Shear beam / Double-ended shear beam: Platforms, tanks, and industrial weighing.

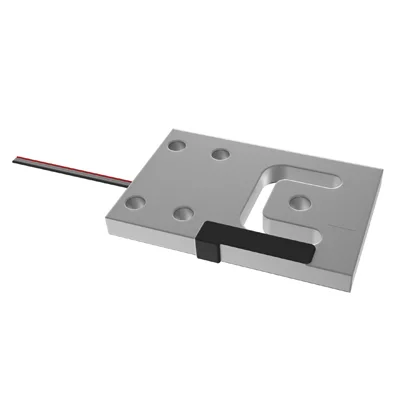

Single-point: Small platforms like retail or bench scales.

Custom load cell: For unusual shapes, loads, or mounting requirements.

5. Decide on Accuracy / Tolerance

Define the precision level you need.

Industrial-grade: ±0.03%–0.1% full-scale accuracy.

Standard applications: ±0.25%–0.5% is usually sufficient.

6. Factor in Environmental Conditions

Check temperature range tolerance.

Ensure IP rating matches dust or water exposure.

Consider chemical resistance if used in corrosive environments.

Assess shock and vibration tolerance.

7. Electrical & Signal Requirements

Choose the right output type: mV/V, 4–20mA, digital signals.

Verify compatibility with your indicator, PLC, or data acquisition system.

Confirm cable length and connector type for your setup.

8. Plan for Installation and Maintenance

Confirm the sensor is easy to install and calibrate.

Check if accessories (mounts, cables, junction boxes) are included.

Determine if you’ll need ongoing maintenance support.

9. Consider Warranty & Support

Buy from official partners to ensure authentic products.

Confirm manufacturer warranty and technical support.

Look for expert guidance for troubleshooting and setup.

10. Evaluate Custom Options

If your project has unique requirements, ask for a custom-built load cell.

Ensure it meets capacity, mounting, and precision needs.

Work with a partner who can design, build, and support the solution.

A load cell is a sensor that measures force or weight. It converts a physical force into an electrical signal that can be measured and monitored. Choosing the right type depends on your application, weight range, accuracy requirements, and installation environment.

Different applications need different load cells:

S-type load cells: Ideal for tension and compression measurements.

Shear beam load cells: Perfect for industrial scales and platform weighing.

Single-point load cells: Great for smaller scales like bench or retail scales.

Custom load cells: For unique requirements, we can design a load cell tailored to your exact specifications. Consider the capacity, mounting, and environment when selecting.

Always select a load cell with a maximum capacity slightly higher than your expected load. Overloading can damage the sensor, while underutilising it may reduce accuracy. Our team can help calculate the perfect capacity for your application.

Accuracy depends on how precise your measurement needs to be. Industrial applications often require 0.03% to 0.1% full-scale accuracy, whereas less critical applications can use standard tolerance cells. Our experts can guide you based on your industry standards.

Yes. Many load cells are IP-rated for dust and water resistance and built from stainless steel or alloy steel for durability. If your environment is extreme — like high moisture, chemicals, or vibration — we can recommend the most suitable model.

By shopping with us, you get genuine VPG load cells backed by manufacturer warranties, technical guidance from certified experts, and access to the latest technology. You’re ensured reliability, longevity, and precise performance.

Absolutely. Our team can design custom load cells for special capacities, shapes, or mounting configurations. If your project requires something outside standard specifications, we’ll engineer a solution that fits perfectly.

Proper installation is key to accurate readings. Factors include correct mounting, wiring, and calibration. We provide technical support, guidance, and resources to ensure your load cells perform accurately from day one.

We provide fast and reliable delivery across Australia, so your project won’t be delayed. Our team can also help choose a solution that’s ready to install and optimised for your application.

Our team of seasoned industry experts is available to advise you at every stage. We analyse your requirements, suggest the ideal type, and even provide custom solutions if needed — ensuring you get the right load cell, every time.

Get Free Consultation & Load Cell Recommendation

Experts’ Insights: Understanding the Full Picture of Load Cells

In the world of precision measurement, understanding the full context behind every sensor, load cell, or gauge is critical. That’s why we break down insights using the 1H & 5W framework — answering Who, What, Where, When, Why, and How. Our experts share practical advice, real-world examples, and tips to help you make informed decisions when choosing, installing, or maintaining your measurement solutions. Whether you’re selecting the right load cell for an industrial platform, calibrating a sensor, or exploring custom-built options, this approach ensures you see the full picture — saving time, reducing errors, and maximising performance.